The Benefits & Uses of Infrared Study Services

Electrical failures can bring operations to a grinding halt, costing businesses thousands of dollars in downtime and repairs. Infrared thermography offers a proactive solution to identify potential problems before they become catastrophic failures. This non-invasive diagnostic technique uses thermal imaging to detect heat patterns that indicate electrical issues, allowing facility managers to address problems during scheduled maintenance rather than emergency shutdowns.

Understanding the benefits and applications of infrared study services helps businesses make informed decisions about their electrical maintenance programs. From manufacturing facilities to commercial buildings, infrared thermography provides valuable insights into equipment condition and performance.

What Are Infrared Study Services?

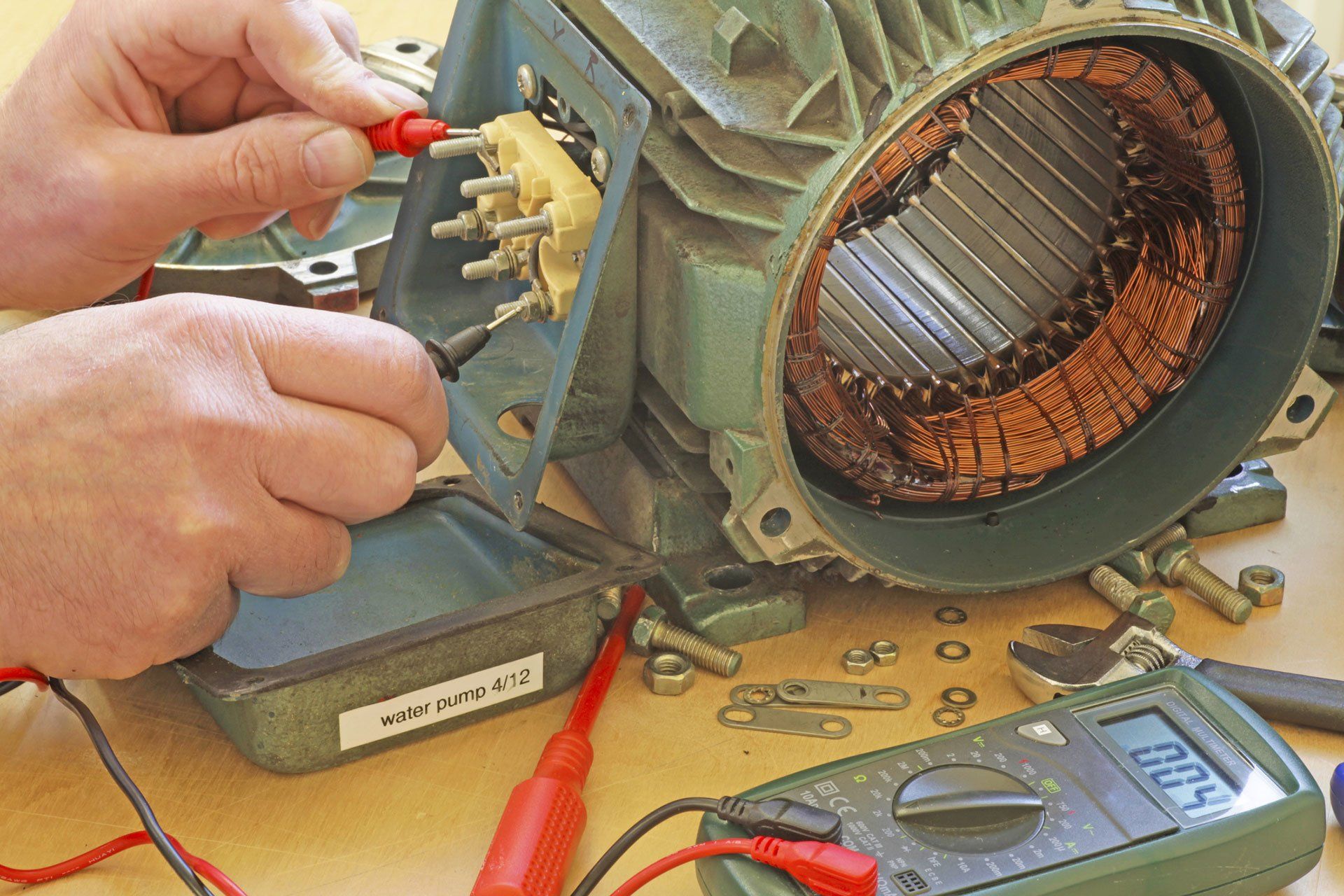

Infrared study services utilize specialized thermal imaging cameras to detect heat signatures from electrical components. These cameras capture temperature variations that are invisible to the naked eye, revealing potential problems within electrical systems. The technology works by measuring infrared radiation emitted by objects and converting it into visual images that highlight temperature differences.

During an infrared study, trained technicians scan electrical panels, connections, transformers, and other components while equipment operates under normal load conditions. This approach allows for real-time assessment of equipment performance without interrupting operations.

How Infrared Thermography Works

Infrared cameras detect electromagnetic radiation in the infrared spectrum, which correlates directly to temperature. When electrical components develop problems such as loose connections, overloaded circuits, or deteriorating insulation, they generate excess heat. This heat signature appears as bright spots or unusual patterns on thermal images. The technology can identify temperature variations as small as 0.1 degrees Celsius, making it highly sensitive to developing issues. Trained technicians analyze these thermal patterns to determine the severity of problems and recommend appropriate corrective actions.

Key Benefits of Infrared Study Services

Early Problem Detection

Infrared thermography identifies electrical issues in their early stages, often months before components fail completely. This early detection capability allows maintenance teams to plan repairs during scheduled downtime rather than responding to emergency failures. Heat patterns reveal problems such as:

- Loose electrical connections

- Overloaded circuits

- Failing insulation

- Unbalanced loads

- Corroded components

Reduced Downtime and Costs

By identifying problems before they cause equipment failure, infrared studies help minimize unplanned downtime. Scheduled maintenance costs significantly less than emergency repairs, and businesses avoid lost productivity from unexpected shutdowns. Regular infrared inspections can extend equipment life by addressing issues before they cause permanent damage. This preventive approach reduces long-term maintenance costs and delays the need for expensive equipment replacements.

Enhanced Safety

Electrical failures can create serious safety hazards, including fires, explosions, and electrocution risks. Infrared thermography helps identify dangerous conditions before they threaten personnel safety or property. Hot spots detected through thermal imaging often indicate conditions that could lead to arc flash events or electrical fires. Addressing these issues promptly protects both people and facilities from potential harm.

Non-Invasive Assessment

Unlike many diagnostic techniques, infrared thermography requires no physical contact with electrical components. This non-invasive approach allows technicians to inspect energized equipment safely without interrupting operations. The ability to conduct inspections while equipment operates under normal conditions provides more accurate assessments than testing performed during shutdowns. Load conditions often reveal problems that might not be apparent when equipment is de-energized.

Common Applications of Infrared Studies

Industrial Facilities

Manufacturing plants and industrial facilities rely heavily on electrical systems to power production equipment. Infrared studies help identify problems in:

- Motor control centers

- Distribution panels

- Power transformers

- Switchgear assemblies

- Electrical connections

Regular thermal inspections prevent costly production interruptions and protect expensive machinery from damage caused by electrical failures.

Commercial Buildings

Office buildings, retail spaces, and other commercial properties benefit from infrared studies to maintain reliable electrical systems. Common inspection areas include:

- Main electrical panels

- Lighting circuits

- HVAC electrical components

- Emergency power systems

- Data center equipment

These inspections help property managers maintain safe conditions for occupants while avoiding disruptions to business operations.

Healthcare Facilities

Hospitals and healthcare facilities require uninterrupted electrical power for critical equipment and patient care. Infrared studies help ensure the reliable operation of:

- Emergency power systems

- Medical equipment circuits

- Operating room electrical systems

- Life support equipment connections

- Backup generator components

The high reliability requirements in healthcare settings make preventive maintenance through infrared thermography particularly valuable.

Data Centers

Computer and communication equipment in data centers generate significant heat and require stable electrical power. Infrared studies identify problems in:

- Uninterruptible power supply (UPS) systems

- Power distribution units

- Server rack connections

- Cooling system electrical components

- Battery backup systems

Even brief power interruptions can cause data loss and service disruptions, making proactive electrical maintenance essential.

Professional Infrared Study Services with Roundhouse Electric & Equipment Co., Inc

At Roundhouse Electric & Equipment Co., Inc, we provide comprehensive infrared study services throughout Midland and Odessa, TX; as well as the surrounding areas. Our certified technicians use advanced thermal imaging equipment to identify electrical problems before they cause equipment failure. Our company offers infrared thermography services for industrial facilities, commercial buildings, and utility installations. Our experienced team can identify system overloads, damaged switchgear, and other electrical issues that could lead to costly failures. Contact us today to request assistance!